Air Heater Coils

Turnbull & Scott is renowned for the design and manufacture of high end, robust Air Heater coils and batteries which are extensively used in industrial process drying applications worldwide. These are designed for use with steam, condensate, water/glycol mixes, thermal oil or other hot process fluids as the heat source.

The most common method for the drying of solids across industries is to introduce hot air to the product and evaporating the moisture contained to required levels.

Trusted OEM Partner

Our heat exchanger coils are widely used by equipment manufacturers involved in such activities as manufacture of paper, films & foils, pharmaceuticals, extraction of plant oils, malting of grains, curing of building materials, baking of foods & snacks, production of aluminium cans, fabrication of textiles, drying of carpets & tiles and of aggregates.

Manufacturing and Process Industries

The company also works hand-in-hand with in-house engineering teams across the manufacturing and processing industries to design bespoke new or replacement air heater coils for their production systems.

Waste Heat Recovery for Process Drying

Reduce Energy consumption by Re-purposing Waste Heat for Process Drying

Ever increasing energy prices and commitments to reduce CO2 emissions force us all to reconsider energy usage and today that includes identifying waste heat sources within our industrial processes and determining how to capture and reuse that waste heat.

Waste heat energy from flue gas and other process heat is commonly around 15-20 % . Much of this can be captured and re-purposed for drying applications, as well as other industrial uses, bringing the potential to reduce fuel consumption by 12-16% as well as an equivalent reduction in CO2 emissions.

Turnbull and Scott typically design and manufacture waste heat recovery solutions from heat sources discharging heat to 560°C using stainless steel heat exchangers and up to 400°C using carbon steel.

Common waste heat sources

- Process waste water/fluids

- Process steam condensate

- Cooling water from high temp. applications

- Steam boiler exhaust

- Gas turbines or engine exhausts

- ORC cooling loops

- Drying ovens/kilns

Click below to read a case study about how we provided a heat transfer system for an aggregates drying manufacturer. If you would like to talk to us about heat recovery for drying, call us or fill out our contact form at the bottom of the page.

Heat Recovery Specialisms:

Industries & Sectors:

- Nuclear

- Textiles

- Paper

- Oil & Gas

- Food Processing

- Distilleries

- Co-generation/CHP plants

- OEMs

Heat Recovery System Design for Dryer Manufacturers

As companies commit to firm carbon reduction targets and roll out low carbon strategies they increasingly require their equipment suppliers to support them in their journeys to net zero. For dryer manufacturers this includes incorporating heat recovery systems in their dryer designs.

Our heat exchanger design team works with dryer manufacturers to assess the potential for heat recovery in their projects, the design options, and associated costs to enable them to meet their customers’ heat recovery requirements.

Click below to read more on how we work with our dryer manufacturer customers on heat recovery .

Custom Dryers

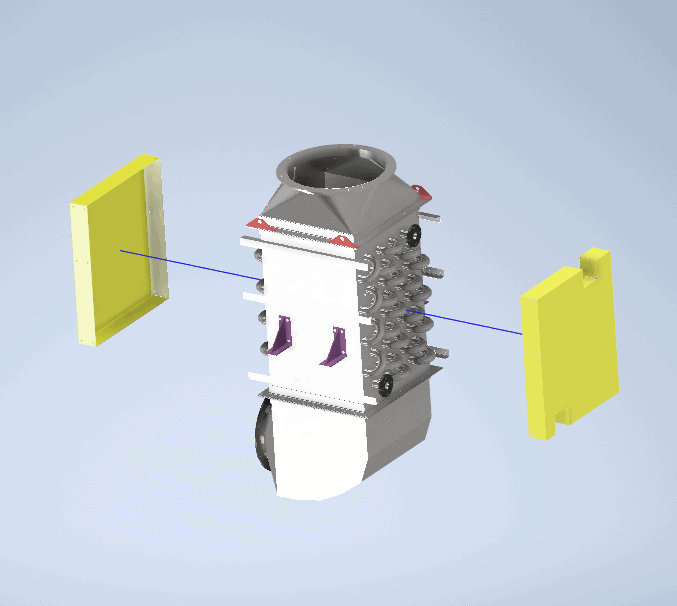

Turnbull and Scott design and manufacture fully packaged skid mounted dryer units or frame based dryer units complete with electric motors and fan assemblies ready for installation.

These are often designed for heating air using hot water (LPHW) from a traditional or biomass boiler or waste heat from a CHP engine for example, but they can also be designed and manufactured for use with steam, thermal oil or other process fluids.

Applications for our packaged driers include the drying of grain, timber, woodchip, wood-pellets as well as other materials. Typical configuration:

- Air Heater Coils- cooper tubes with aluminium fins (carbon or stainless steel as alternatives) and galvanised steel casing

- Fan with 3 phase 415V electric motors

- Skid based stainless steel frame to facilitate placement by forklift

- Range of control options -cost saving inverter to control fan motor speed or automatic fan controls