What is Net Zero and understanding how we can help

Net Zero refers to achieving a balance between the amount of greenhouse gas emissions produced and the amount removed from the atmosphere. In short, achieving Net Zero means no longer adding to the total amount of greenhouse gases in the atmosphere.

Specialising in the generation, transfer and recovery of heat, Turnbull & Scott can help you achieve your Net Zero target through our customised products and services.

Understand more about Net Zero

Some might speak slightly negatively around the chances of working toward Net Zero, but Turnbull & Scott is a living proof that companies can adapt to this way of thinking. It is great to see a Scottish company doing this all while encouraging local workers and apprentices to be a part of it.

Gillian Martin

The Scottish Minister for

Energy and the Environment

Gillian Martin

The Scottish Minister for

Energy and the Environment

The Intergovernmental Panel on Climate Change (IPCC) stated in 2018 that the world needs to reach Net Zero by around 2050 if it is to meet the Paris Agreement target of limiting global warming to 1.5°C. To better protect the environment, governments around the world have proposed their own Net Zero targets. For example, in 2021, the UK government published a policy paper on the Net Zero Strategy, which outlines the policies and proposals for decarbonizing all sectors of the UK economy to meet the Net Zero target by 2050.

As a responsible organization operating in the UK, we are aligned with this national target and are actively working towards it, supporting customers across many industries on their journeys to Net Zero. Along the way, we, like our customers, have had to learn a new Net Zero language which has however helped us contextualize how we ‘fit in’ on our customers’ journeys.

On-site flue gas analysis service & waste heat characterisation studies

Flue/Exhaust gas heat recovery coils & ducting systems

Thermal Energy Storage/Long Duration Energy Storage design, prototyping & build

Chillers & Dry Air Coolers

with

Free Cooling

Chillers with low Global-warming potential(GWP) refrigerants

Chiller system

heat recovery

(retrofit or integral)

On-site flue gas analysis service & waste heat characterisation studies

Chillers & Dry Air Coolers

with

Free Cooling

Low temperature water-fed heat emitters – unit heaters, finned tube radiators & custom designed finned tube

Low temperature water-fed heat emitters – unit heaters, finned tube radiators & custom designed finned tube

Flue/Exhaust gas heat recovery coils & ducting systems

Chillers with low Global-warming potential(GWP) refrigerants

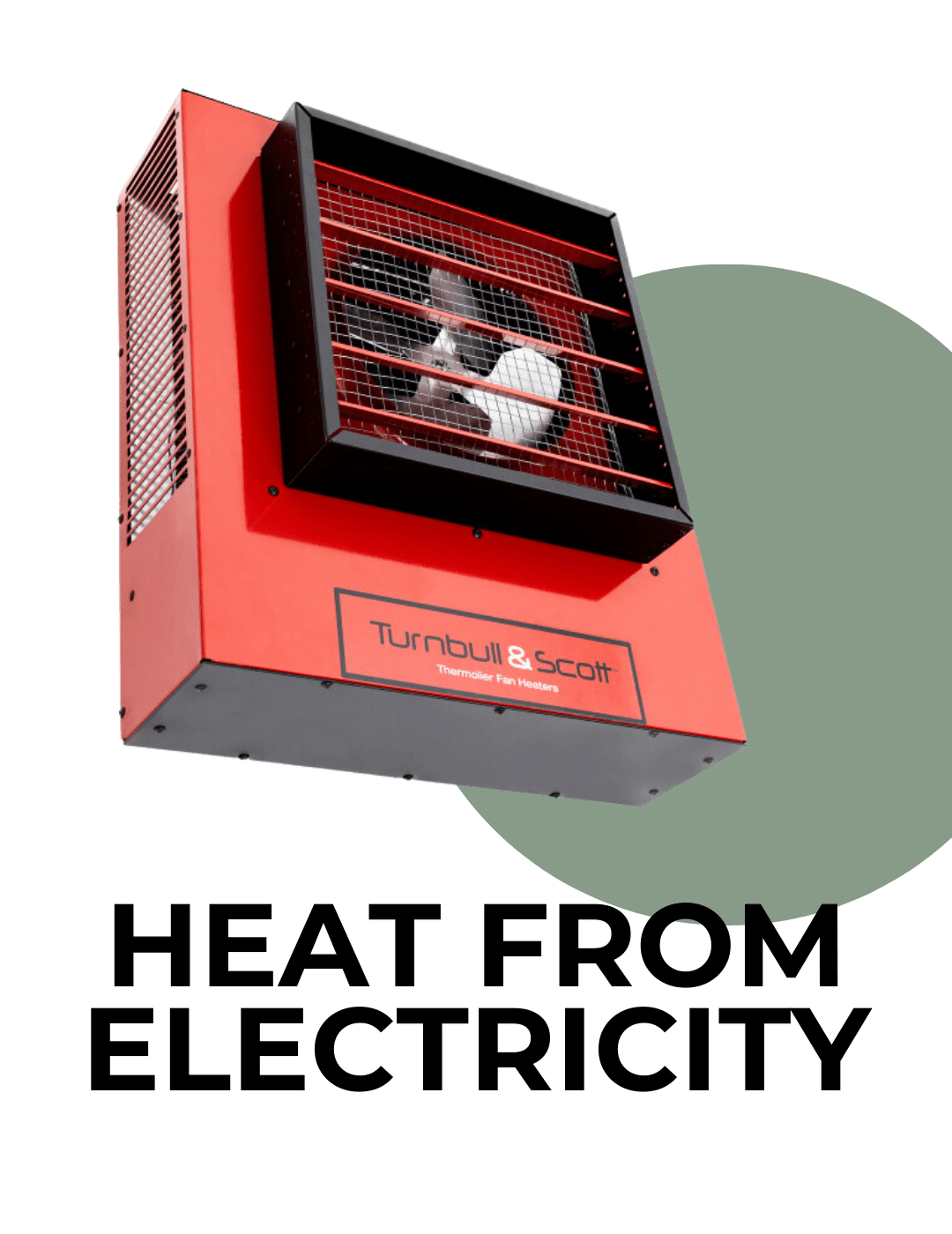

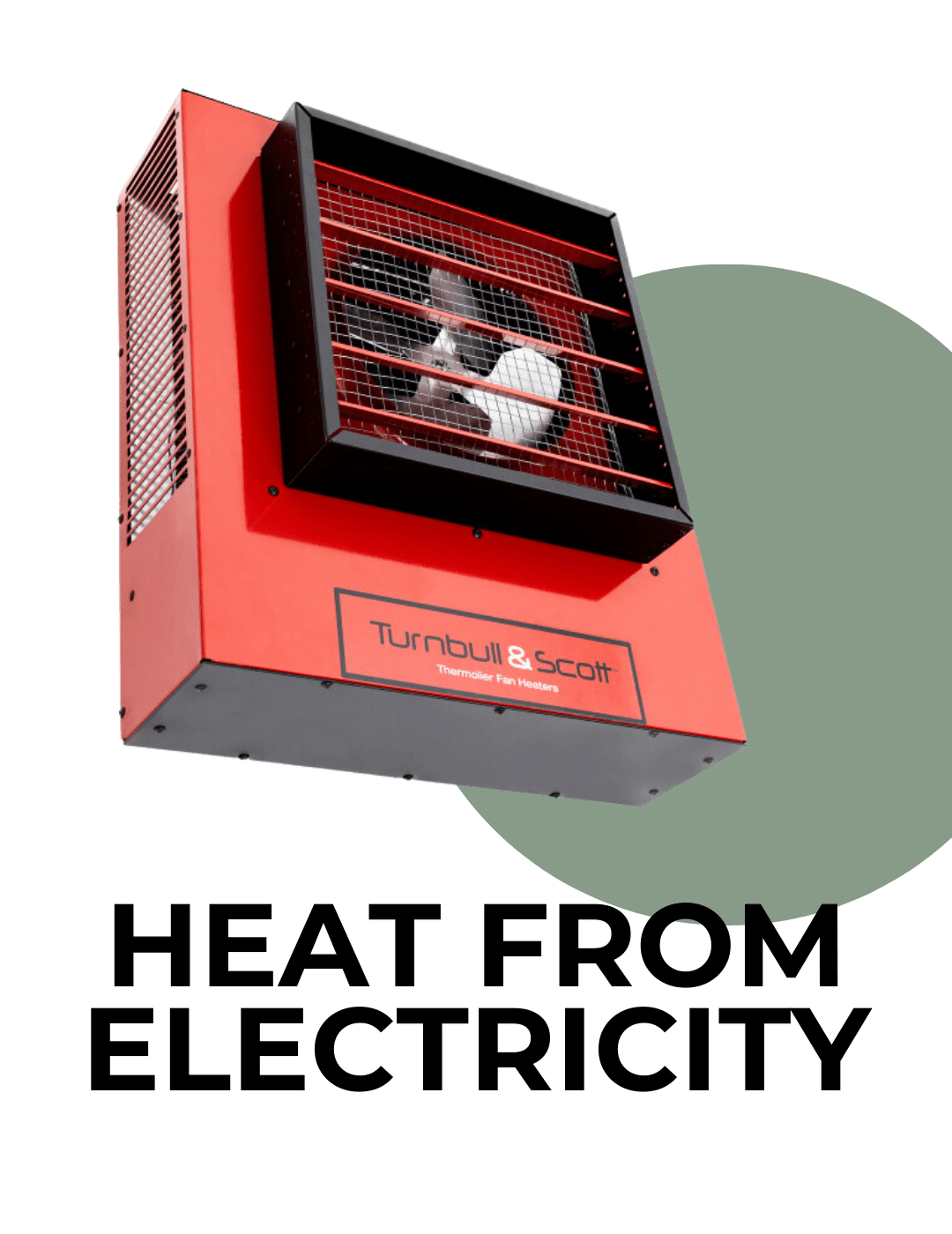

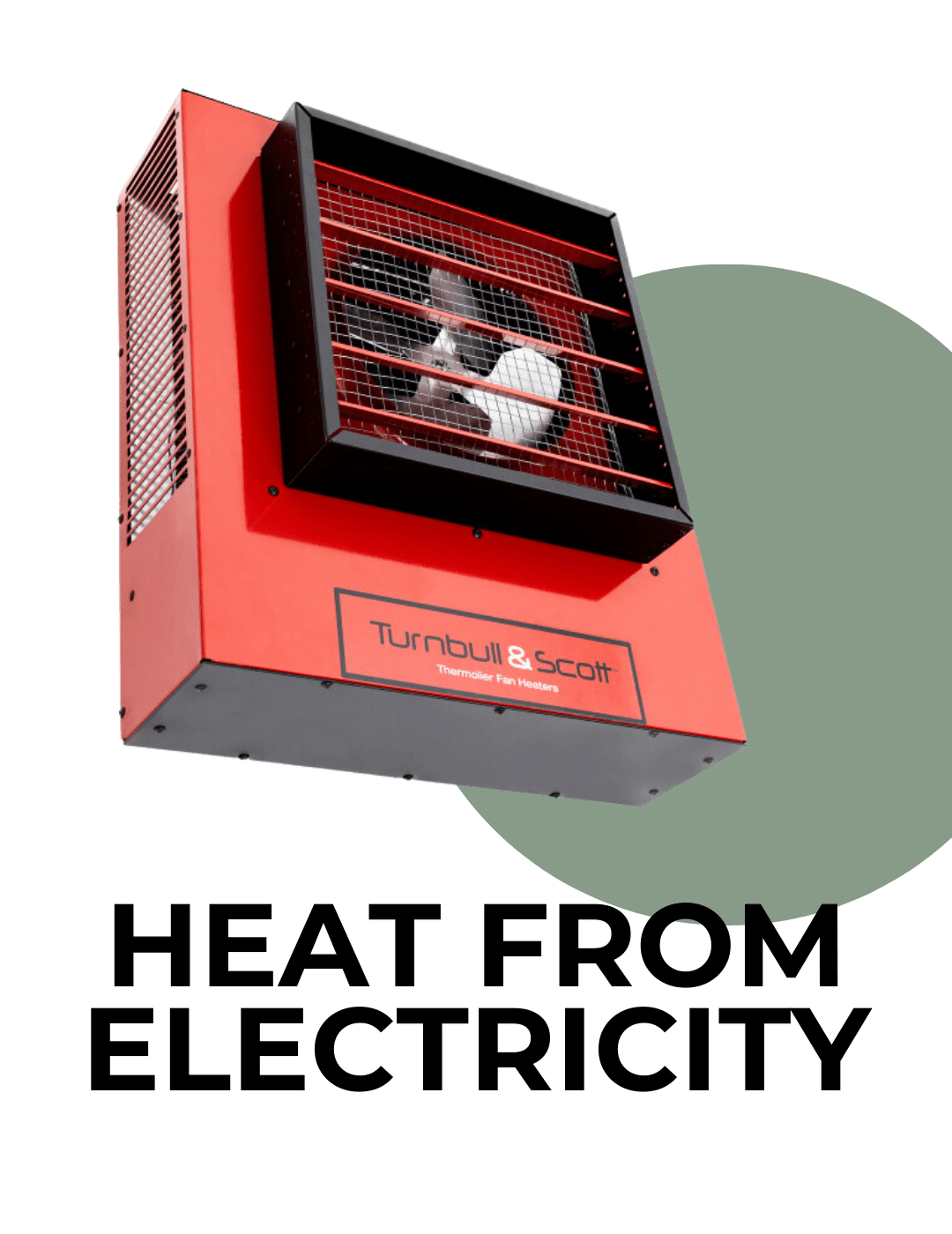

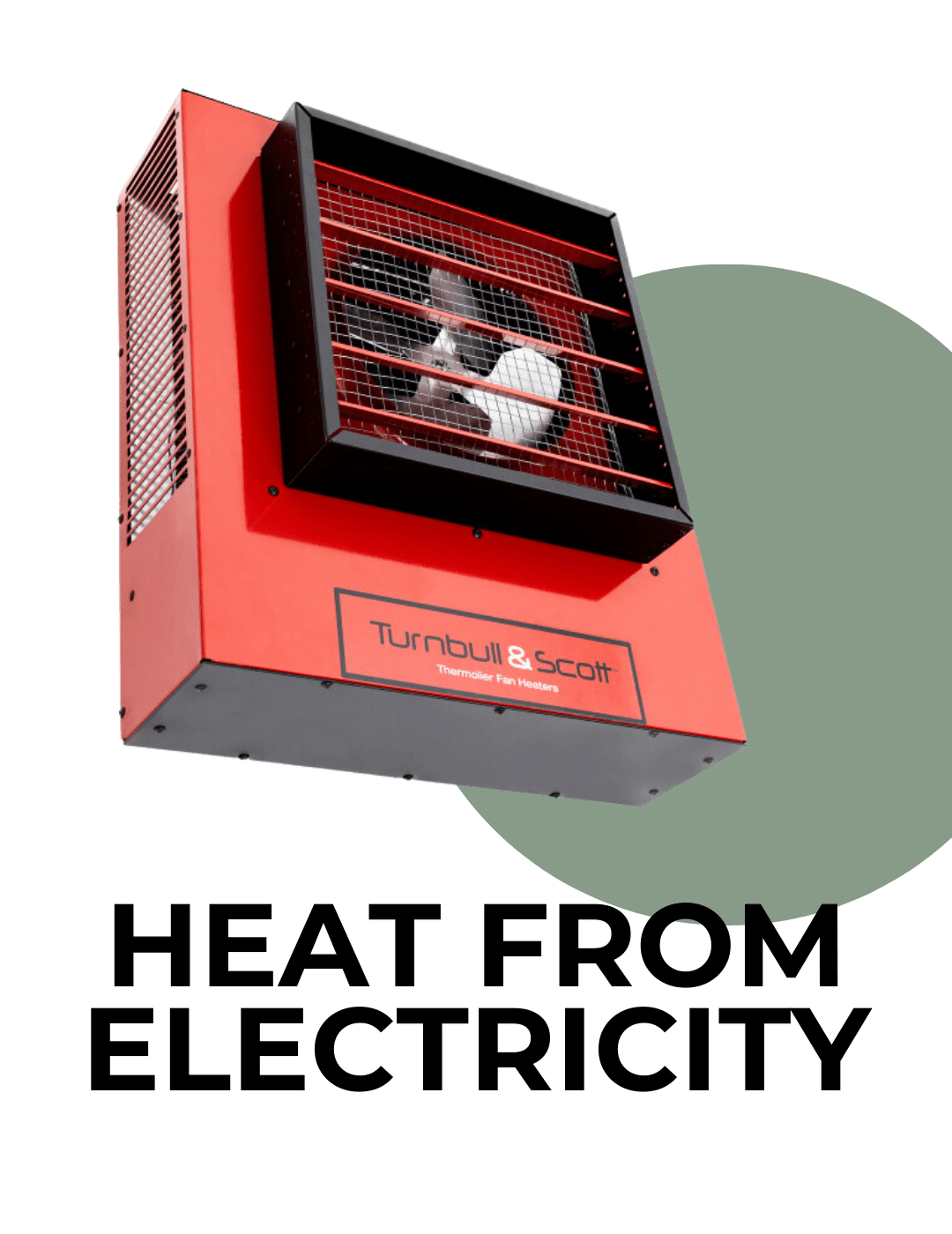

Industrial Electric

Unit Heater-

Electric Thermolier

Industrial Electric

Unit Heater-

Electric Thermolier

Thermal Energy Storage/Long Duration Energy Storage design, prototyping & build

Chiller system

heat recovery

(retrofit or integral)

Heat Pumps to cascade low grade recovered heat to higher temperatures

Heat Pumps to cascade low grade recovered heat to higher temperatures

For more information about how we can help you with your journey to Net Zero, please download our Net Zero brochure.

Our previous work